Certified Intumescent Paint Services in Jeddah | Leading Passive Fire Protection Experts

In the Kingdom’s thriving Western Region, particularly in Jeddah, the integrity of modern steel-framed structures—from colossal commercial towers to essential industrial plants—is paramount. The challenge lies in steel’s vulnerability: when exposed to fire, it loses approximately 50% of its load-bearing capacity at temperatures around $550^\circ C$, leading to rapid structural collapse. Qasr Al Himayah provides the definitive defense against this failure through specialized, certified Intumescent Paint Services in Jeddah. We are not merely applicators; we are Passive Fire Protection (PFP) engineers dedicated to safeguarding infrastructure and human life across KSA.

As a highly trusted and locally focused contractor, our mission is to ensure that every application of Intumescent Paint guarantees two things: strict compliance with local Saudi Civil Defense (SCD) regulations and adherence to stringent international standards (including UL, ASTM, and EN standards). Our bespoke solutions ensure your structural steel remains functional and aesthetically pleasing, a necessity for exposed architectural elements in modern Jeddah construction.

Request a Project Quote

Chat via WhatsApp

We approach every project in Jeddah as an engineering challenge. The core of our service is the precise calculation of the steel section factor ($\mathbf{H_p/A}$, the ratio of the perimeter exposed to fire versus the cross-sectional area). This factor, combined with the required Fire Resistance Period (FRP) of R30, R60, R90, or R120, determines the exact Dry Film Thickness (DFT) necessary. Utilizing the technical specifications of world-leading manufacturers—such as Jotun, Sherwin-Williams Firetex, Hempel, and Nullifire—we select the coating system that is perfectly optimized for the steel mass, location, and aesthetic demands of your specific structure.

The Mechanism: How Intumescent Paint Services Buys Critical Time

The term “intumescent” describes the coating’s ability to swell or char. When the ambient temperature reaches approximately $200^\circ C$ to $250^\circ C$, the coating undergoes a rapid, complex endothermic chemical reaction. This process creates a thick, highly insulating, carbonaceous foam layer (a “char”) that can expand up to 100 times its original DFT.

This char layer is the structural element’s thermal shield. It performs two life-saving functions:

- Thermal Insulation: The low-density char significantly slows heat transfer to the steel substrate.

- Structural Integrity Maintenance: By delaying the temperature increase, the coating ensures the steel remains below the critical $550^\circ C$ temperature threshold for the duration of the required fire rating.

This vital time delay is the foundation of modern fire safety, facilitating safe evacuation for personnel and enabling emergency response teams in Jeddah to effectively contain the blaze before structural failure occurs.

Tailored Intumescent Paint Services for Jeddah’s Unique Environment

Jeddah’s coastal location presents specific challenges, including high humidity and corrosive salt spray. We specialize in deploying the correct type of intumescent coating compatible with the environment, ensuring long-term durability and performance:

- Water-Based Thin-Film Intumescents: Best suited for controlled, interior environments (C1/C2 conditions) where fast application and low VOCs are key, such as malls and offices in Jeddah.

- Solvent-Based Thin-Film Intumescents: Provides higher weather resistance (up to C3/C4 environments) and faster drying times, often preferred for partially exposed steelwork.

- Epoxy-Based Thick-Film Intumescents: The ultimate solution for extreme environments (C5 and hydrocarbon fires), commonly used in petrochemical plants and offshore facilities near Jeddah, offering superior durability and corrosion resistance.

Our Intumescent Paint Services team ensures that the entire system—including the anti-corrosive primer and the decorative/protective topcoat—is fully tested and certified as compatible, guaranteeing the entire Passive Fire Protection envelope performs as specified.

Precision Application and Unwavering Quality Assurance of Intumescent Paint Services

The performance of intumescent paint is entirely reliant on the precision of its application. Qasr Al Himayah adheres to an uncompromised, five-step quality control process that meets and exceeds industry best practices:

- Surface Preparation (SA 2.5 Standard): Every steel surface is abrasive blast-cleaned to the Near White Metal (SA 2.5) standard. This rigorous preparation removes all rust, mill scale, and contaminants, creating the optimal profile (anchor pattern) for maximum coating adhesion, a non-negotiable step for fireproofing reliability.

- Primer Application & Film Check: A certified primer is applied, and its DFT is checked. Primer compatibility with the chosen intumescent product is confirmed through technical data sheets and site testing.

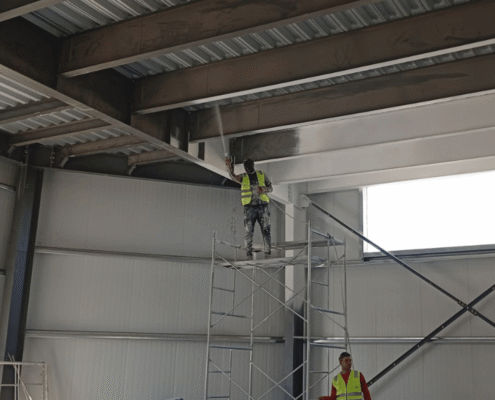

- Intumescent Mid-Coat Application: Utilizing specialized airless spray equipment, our certified technicians apply the coating in multiple, controlled passes to achieve the mathematically derived target DFT.

- Real-Time DFT Verification: Crucially, we use calibrated electronic Dry Film Thickness gauges (as per SSPC-PA 2 standards) to measure the thickness of the coating on every single structural member. This verification is performed during and after application to ensure the fire rating is achieved with zero tolerance for deficiency.

- Documentation and Handover: A comprehensive Quality Assurance/Quality Control (QA/QC) package is compiled. This includes DFT logs, material batch certificates, third-party inspection reports, and the final certificate of conformance required by Saudi Civil Defense inspectors in the Makkah region for project sign-off.

Economic and Regulatory Benefits of Intumescent Paint Services for Projects in Jeddah

Investing in certified Intumescent Paint Services provides long-term financial and operational advantages beyond mere compliance:

- Project Continuity and Compliance: Failure to meet SCD fire codes can result in significant project delays, fines, or loss of occupancy permits. Our certified process guarantees approval, minimizing risk and ensuring timely project handover.

- Aesthetic Value: Unlike bulkier alternatives like cementitious sprays or fire board, thin-film intumescents preserve the sleek, contemporary look of exposed architectural steel, a major factor in modern Jeddah commercial and residential developments.

- Reduced Insurance Premiums: Buildings with certified, high-quality PFP systems and Intumescent Paint Services often qualify for lower insurance premiums, reflecting the decreased risk of catastrophic structural loss.

- Vision 2030 Alignment: By adhering to world-class safety and quality standards, our clients contribute directly to the Kingdom’s goal of building resilient, safe, and technologically advanced urban centers in the Western Region.

Ready to Protect Your Structural Investment with Intumescent Paint Services?

Choosing the right fire protection coating contractor is the most critical decision in securing your building’s lifespan and safety profile. Do not compromise on precision, material quality, or compliance documentation. Partner with Qasr Al Himayah, the certified experts in high-performance Intumescent Paint Services in Jeddah.

Contact us today to schedule an engineered consultation on Intumescent Paint Services. Our technical team is ready to analyze your structural drawings, calculate your specific DFT requirements, and provide a comprehensive proposal for certified Passive Fire Protection that meets every regulatory and aesthetic need.

Or call our Jeddah office directly at +966504165889 for immediate support.