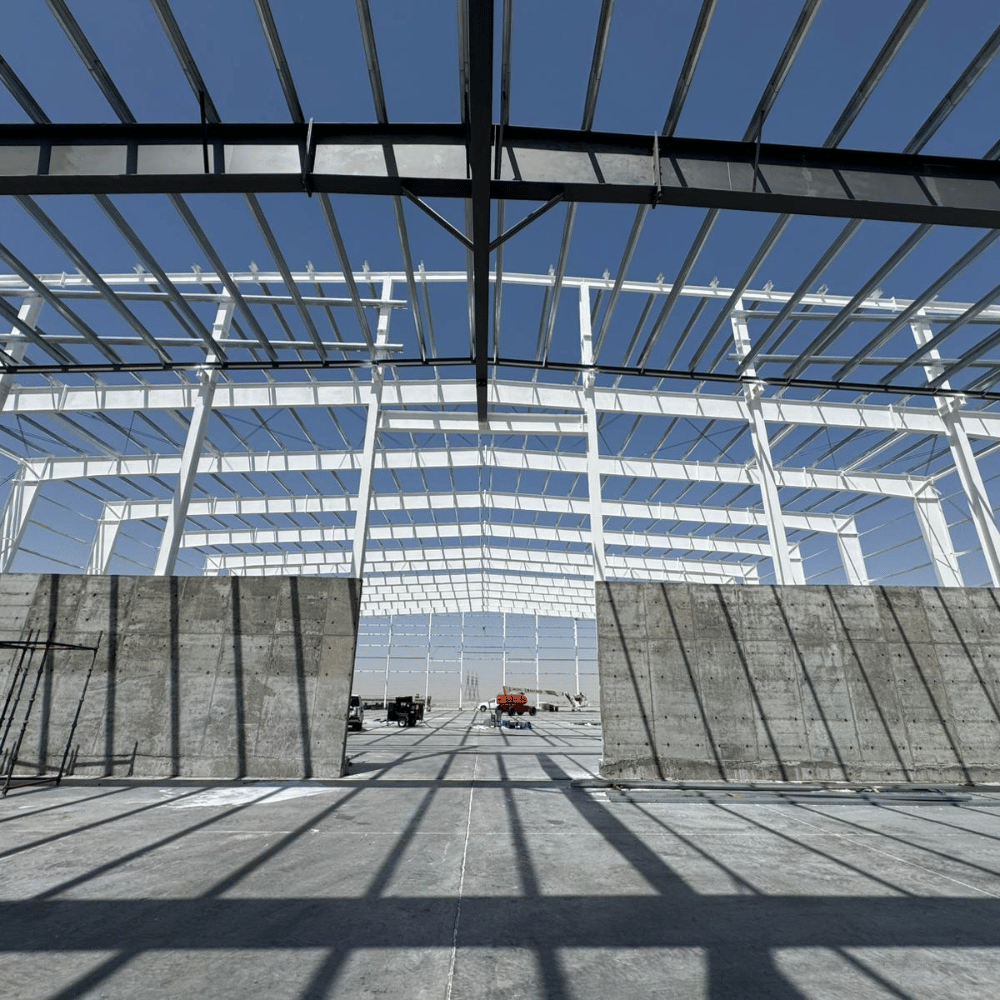

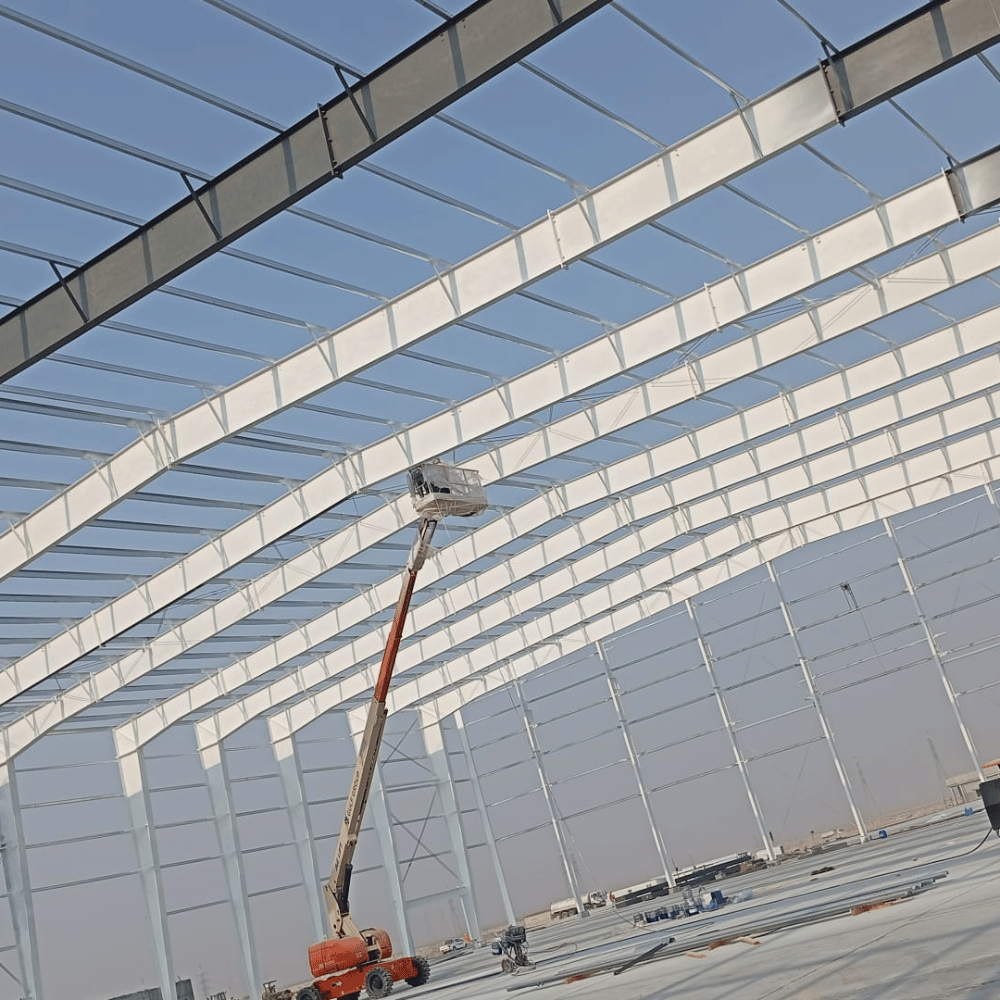

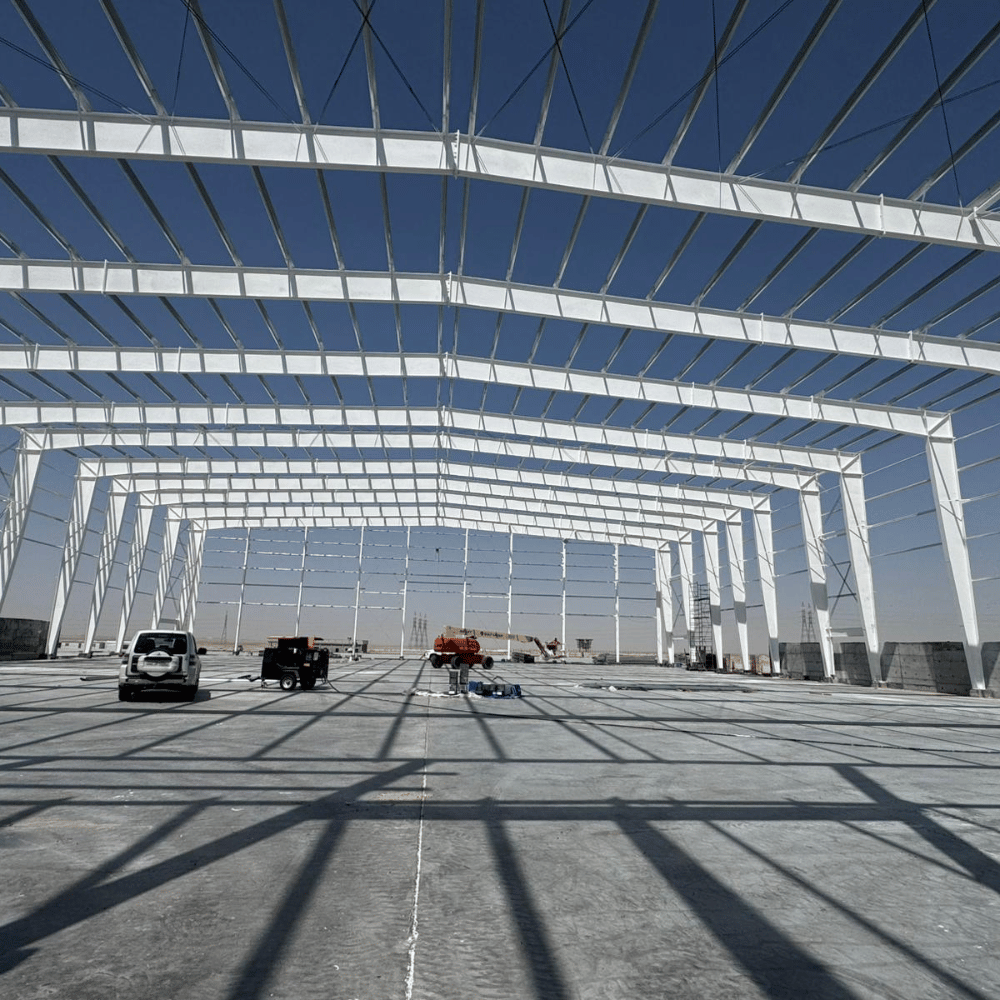

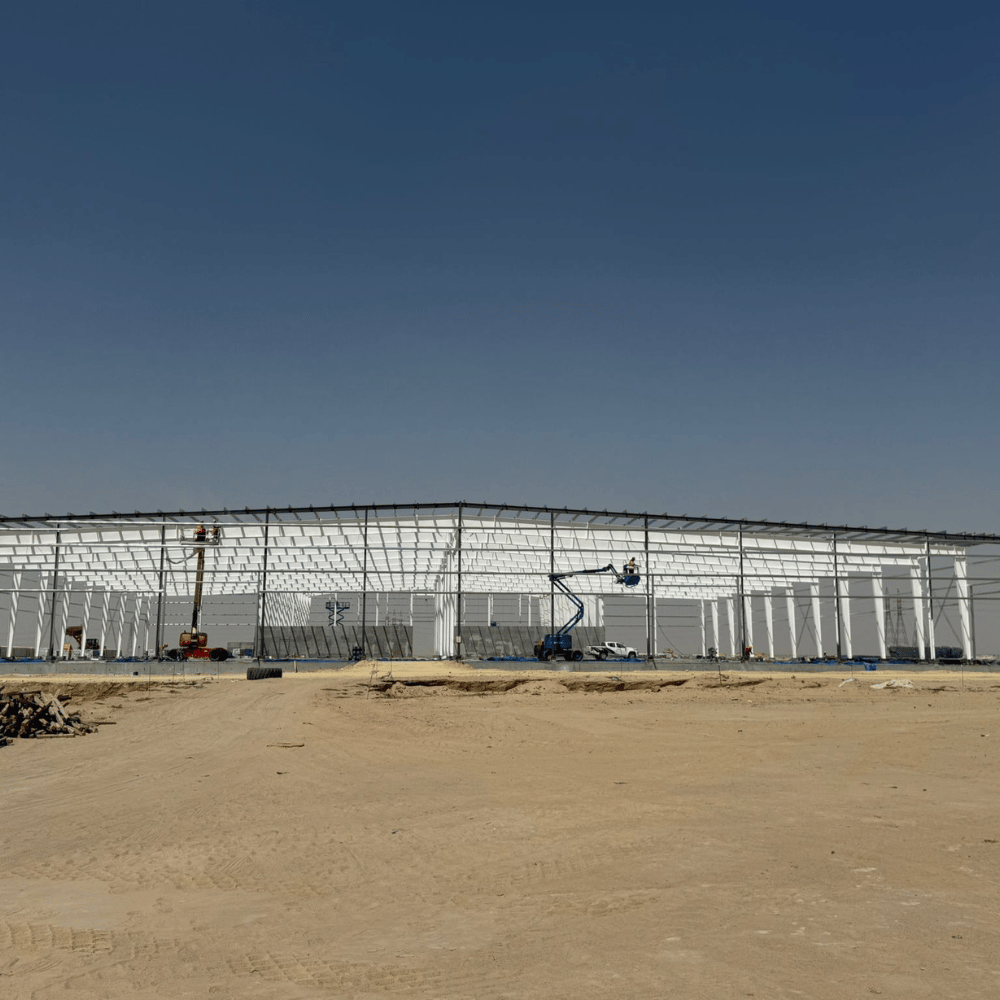

Qasr Alhimaya

Our Services

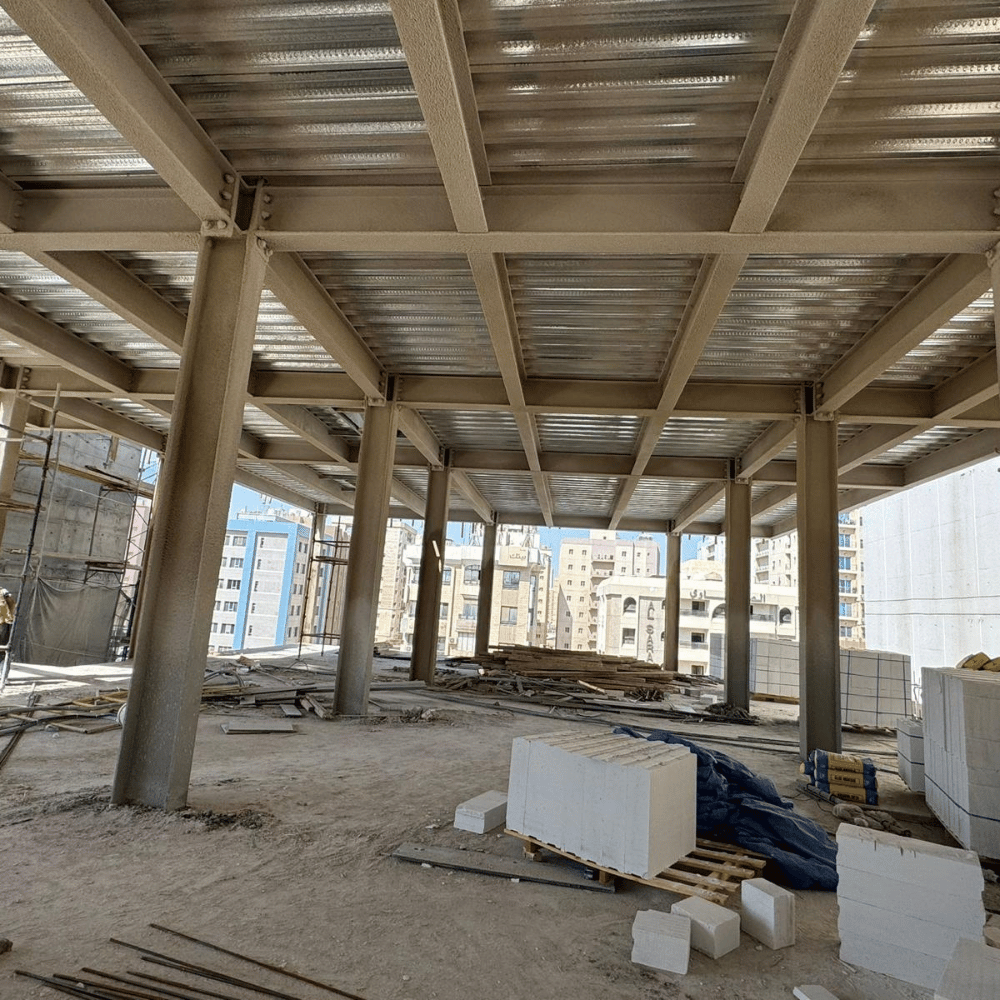

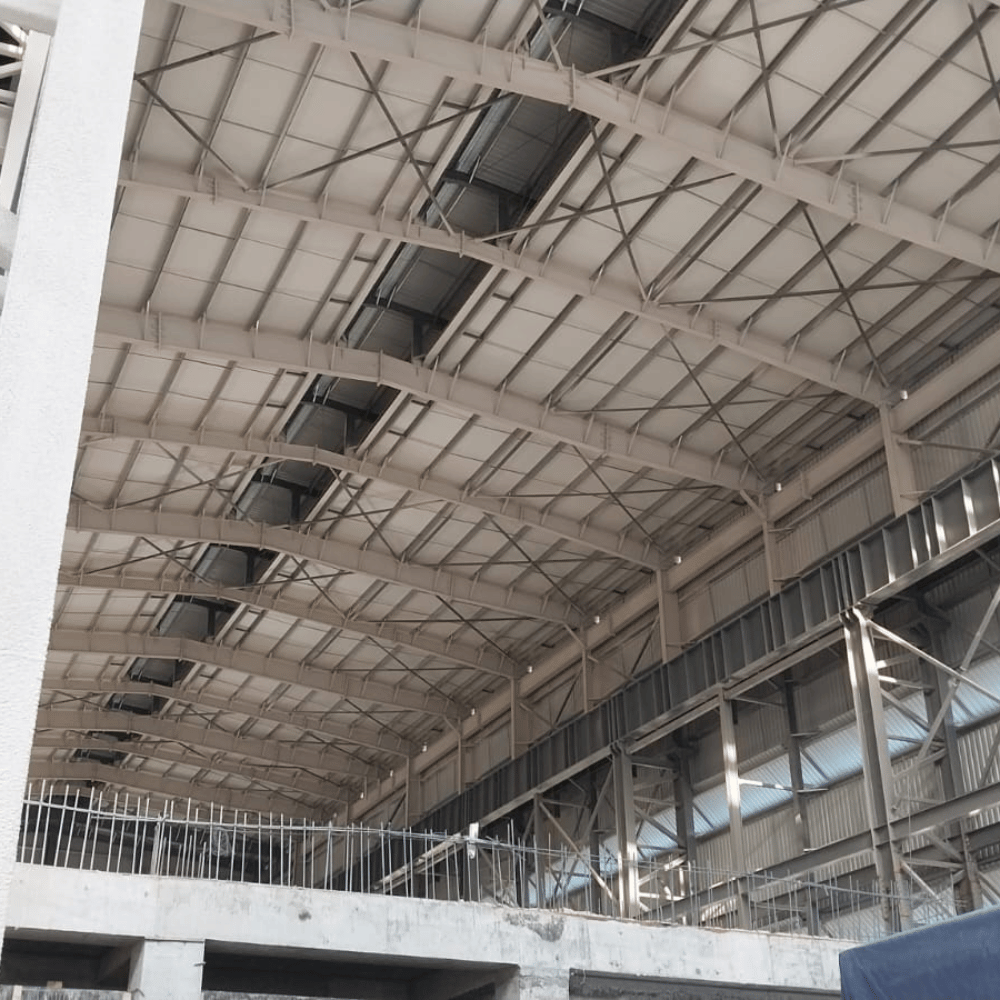

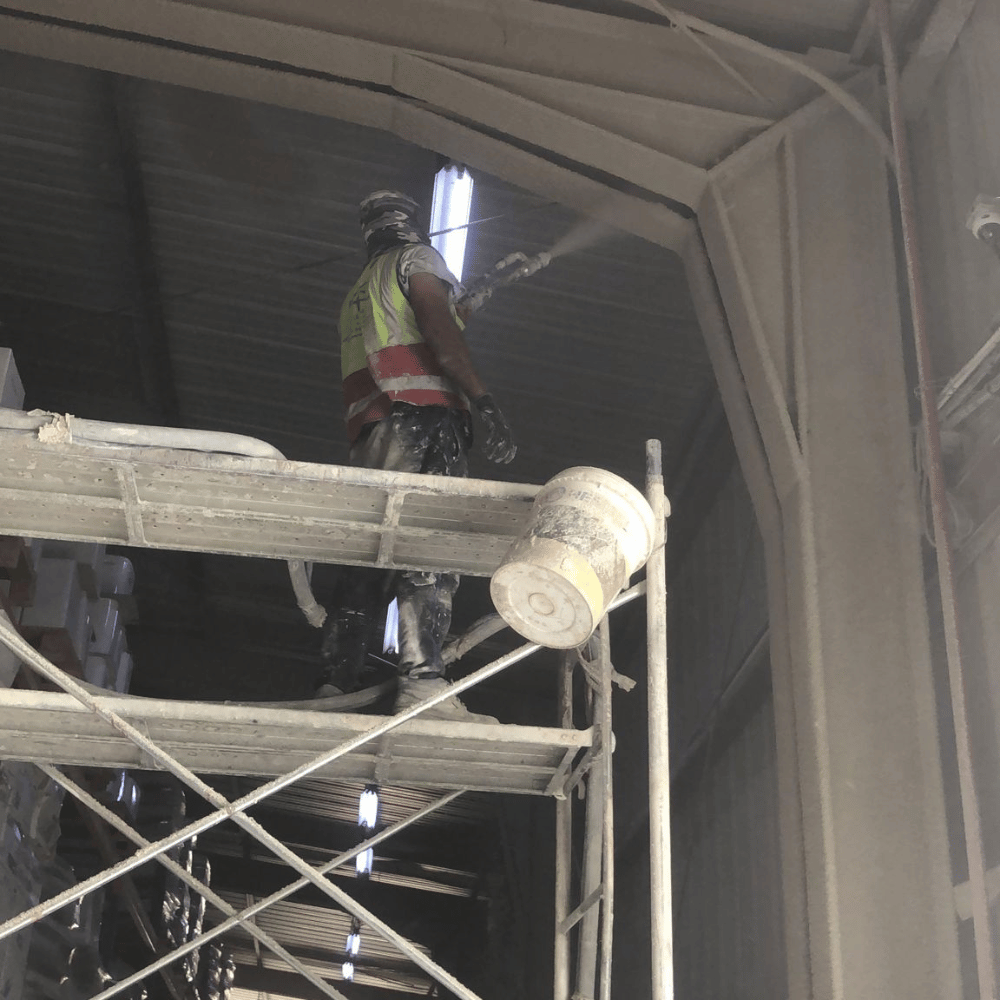

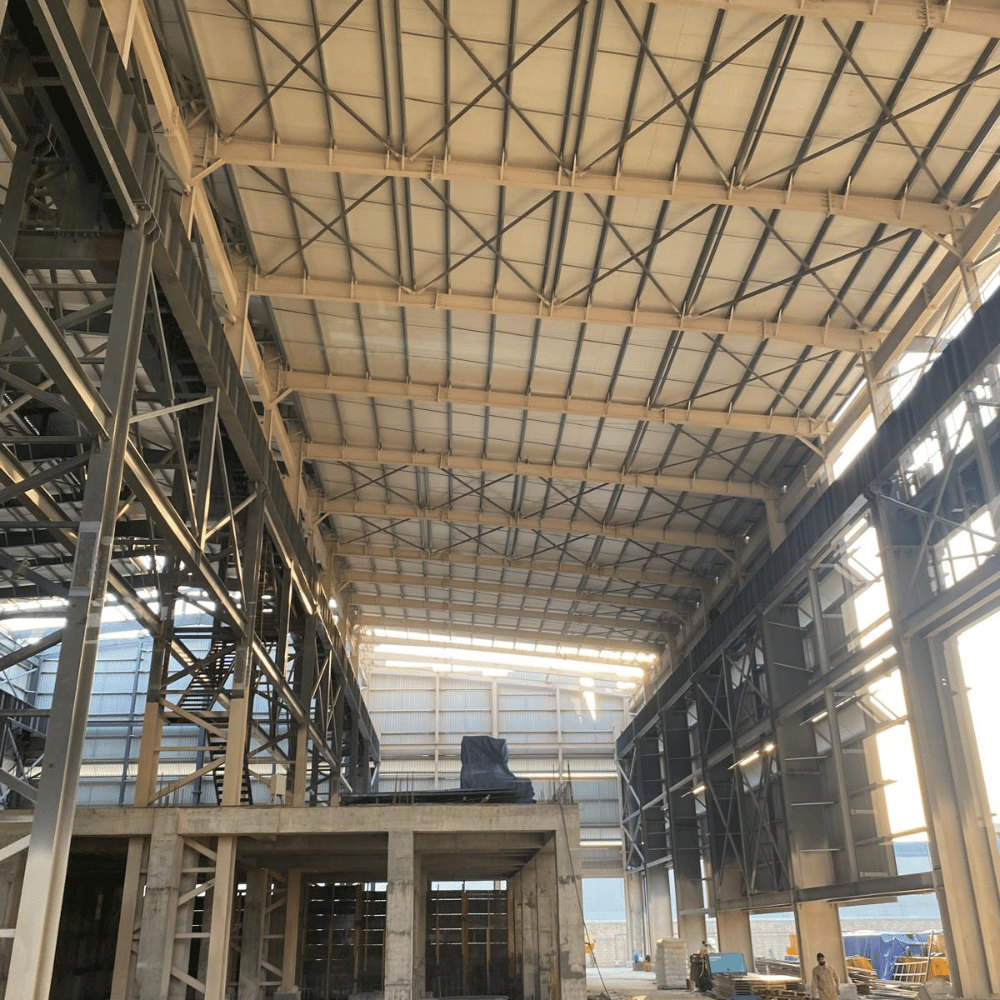

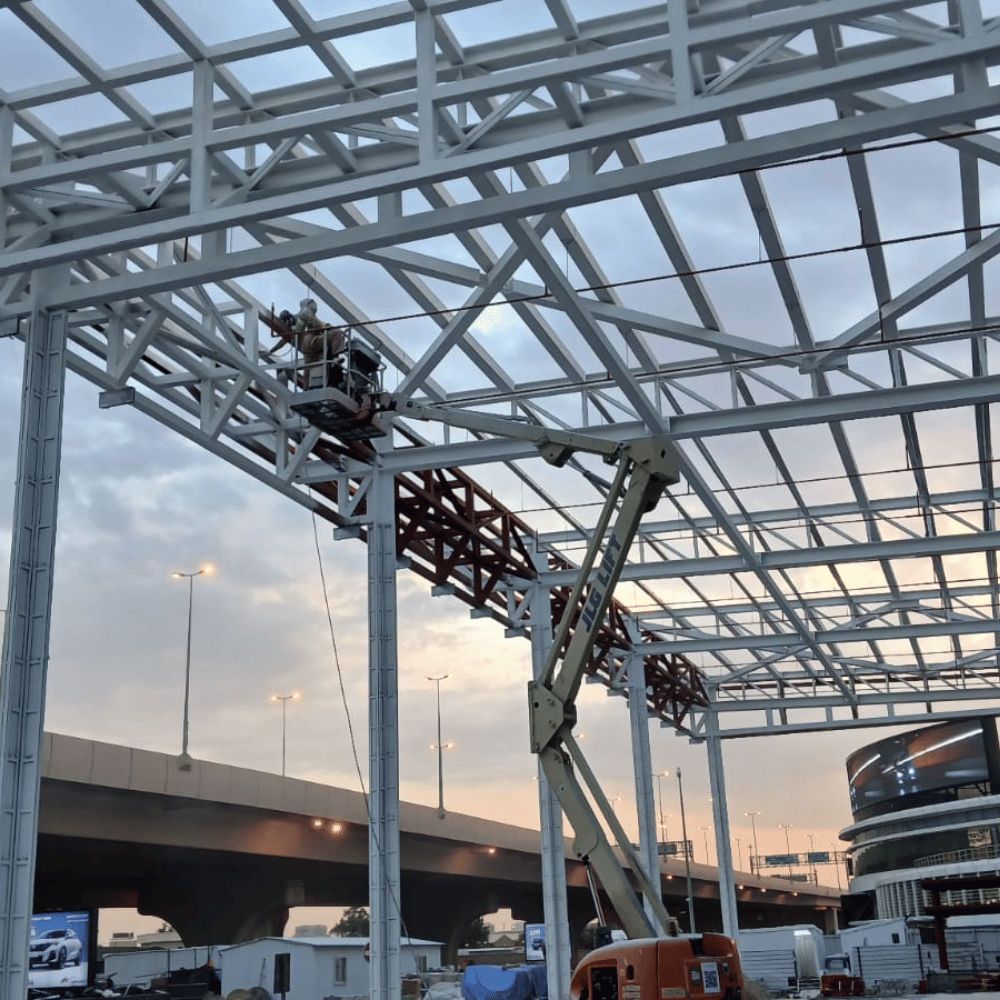

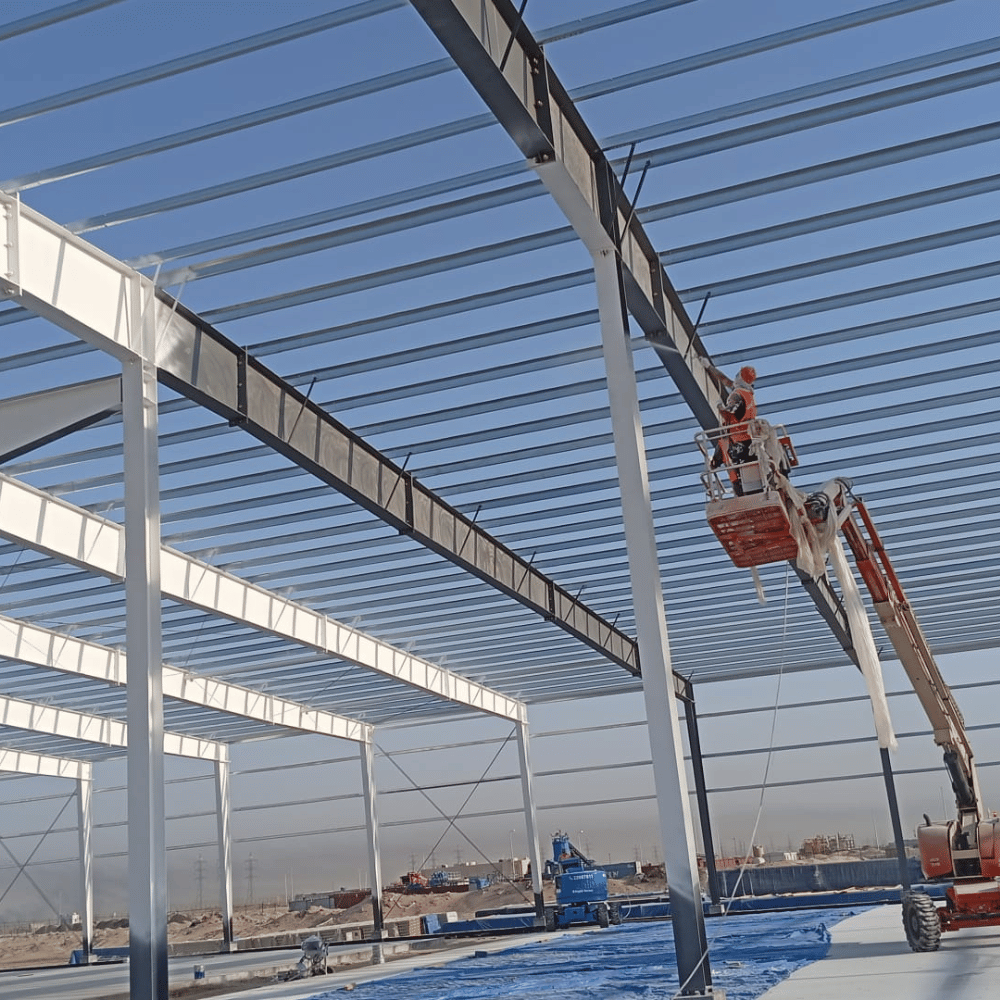

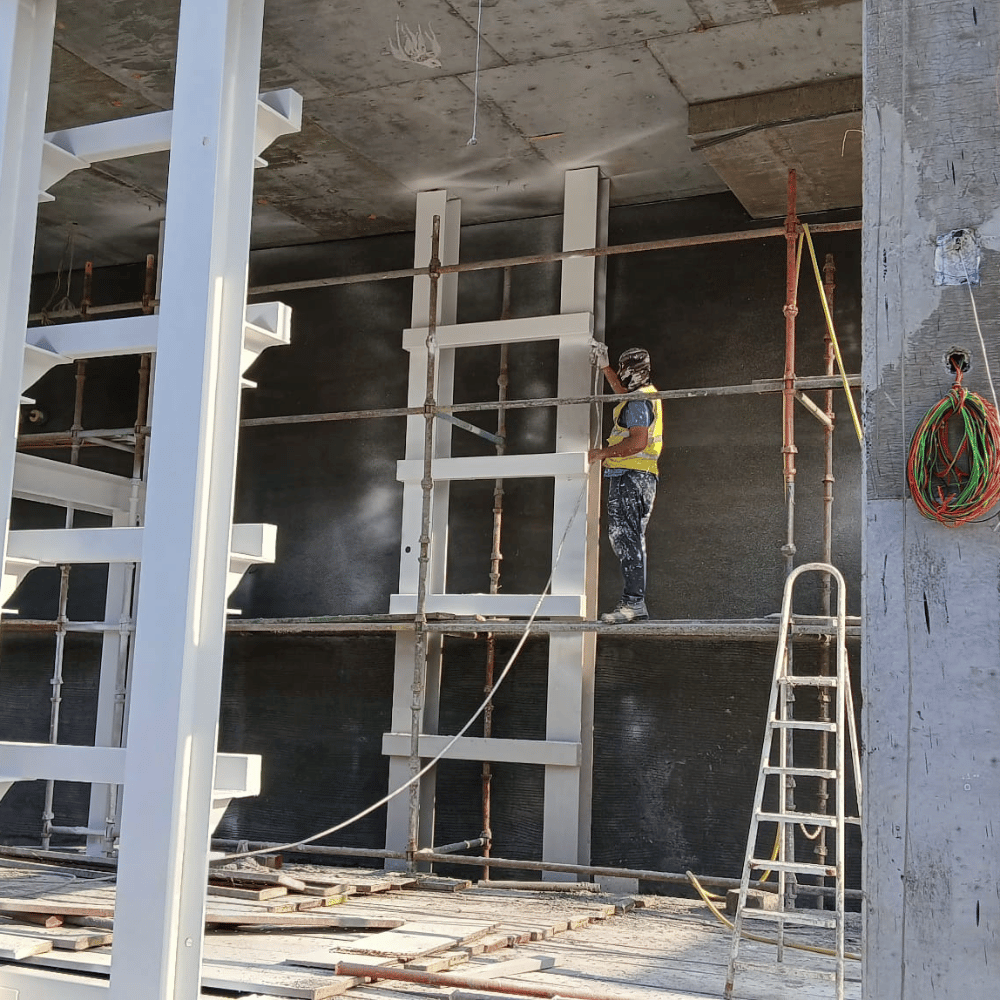

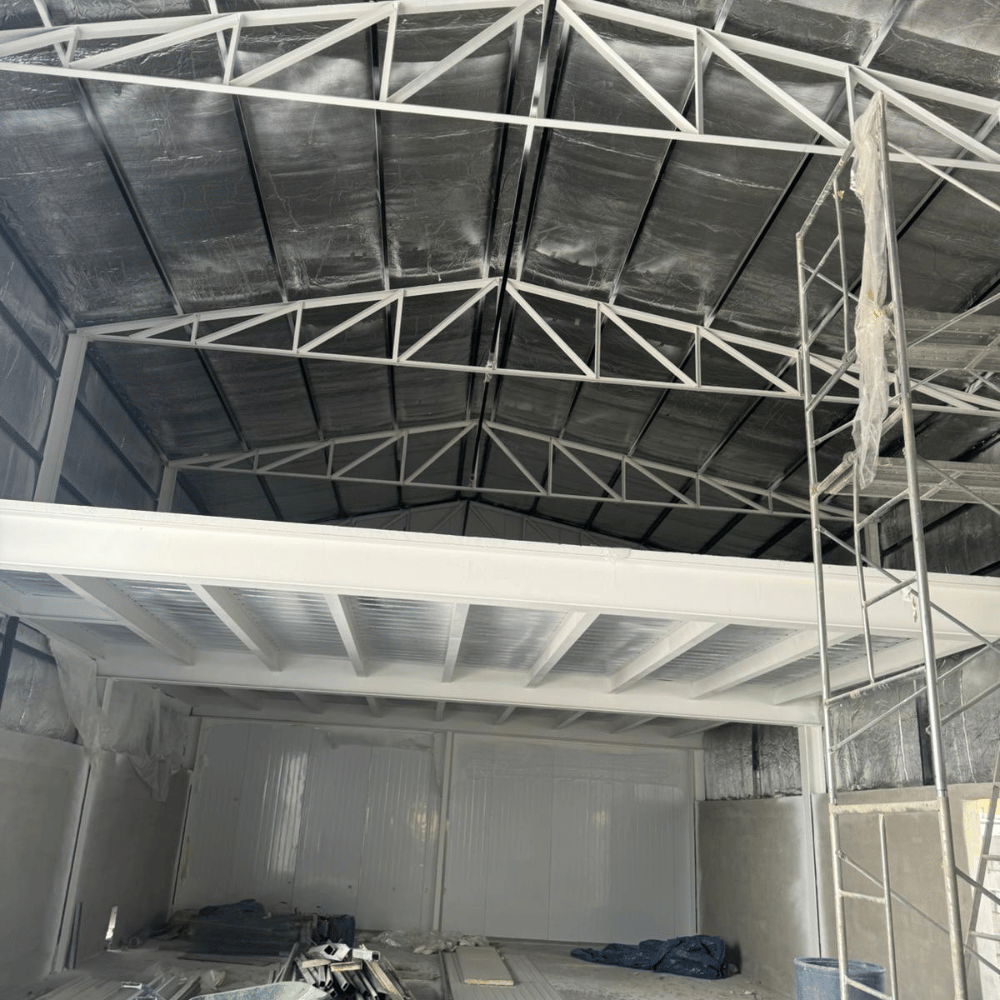

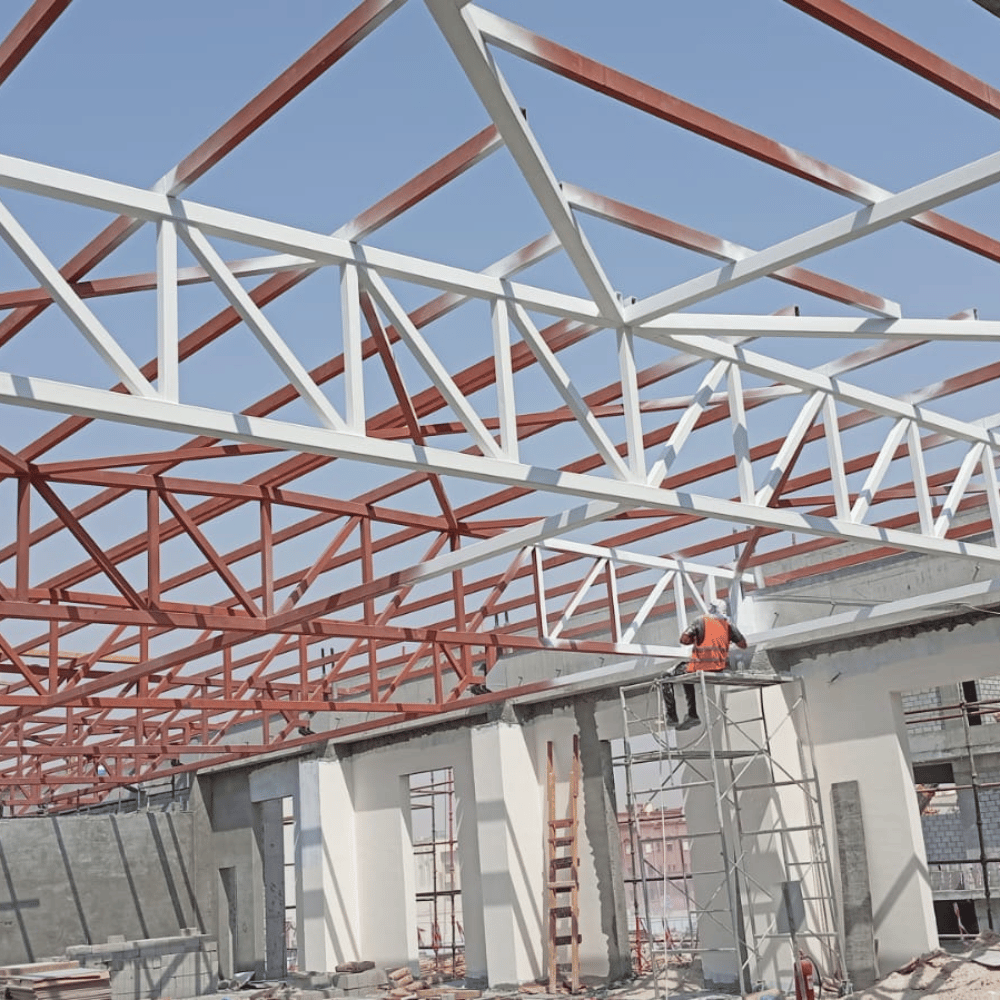

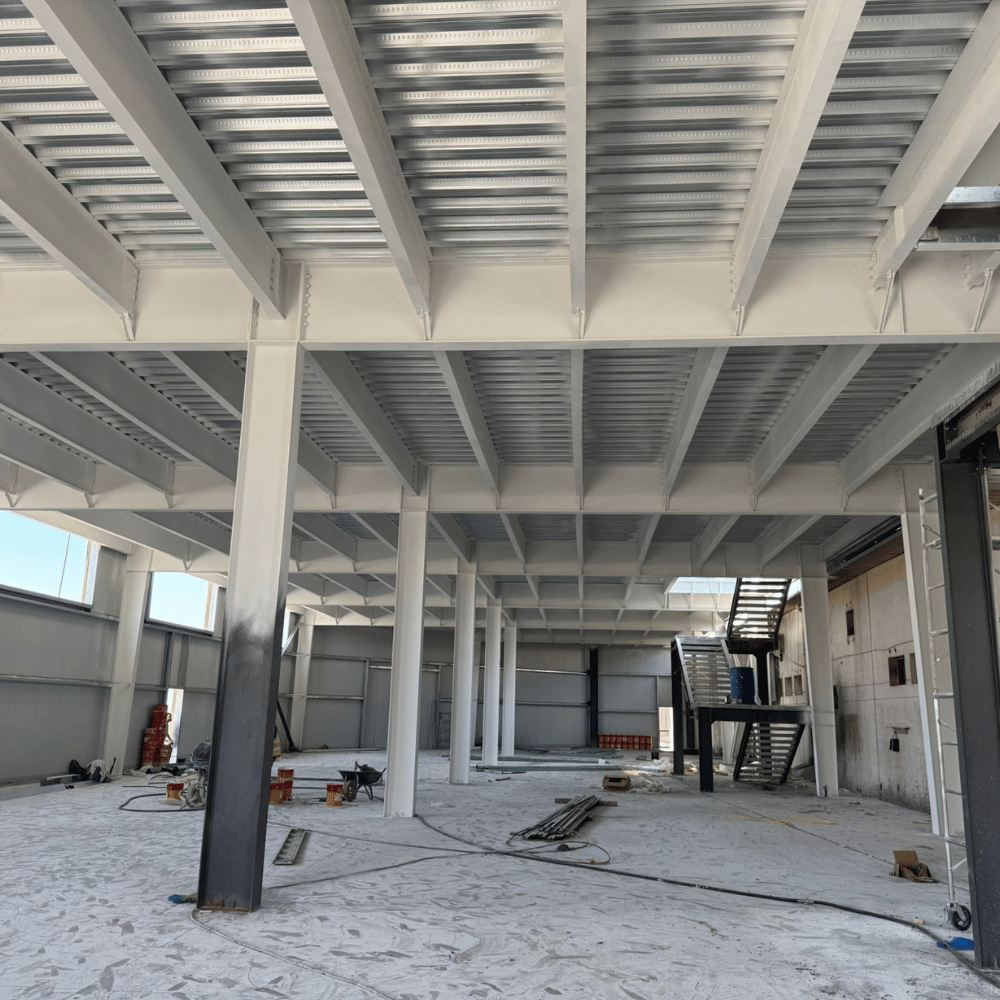

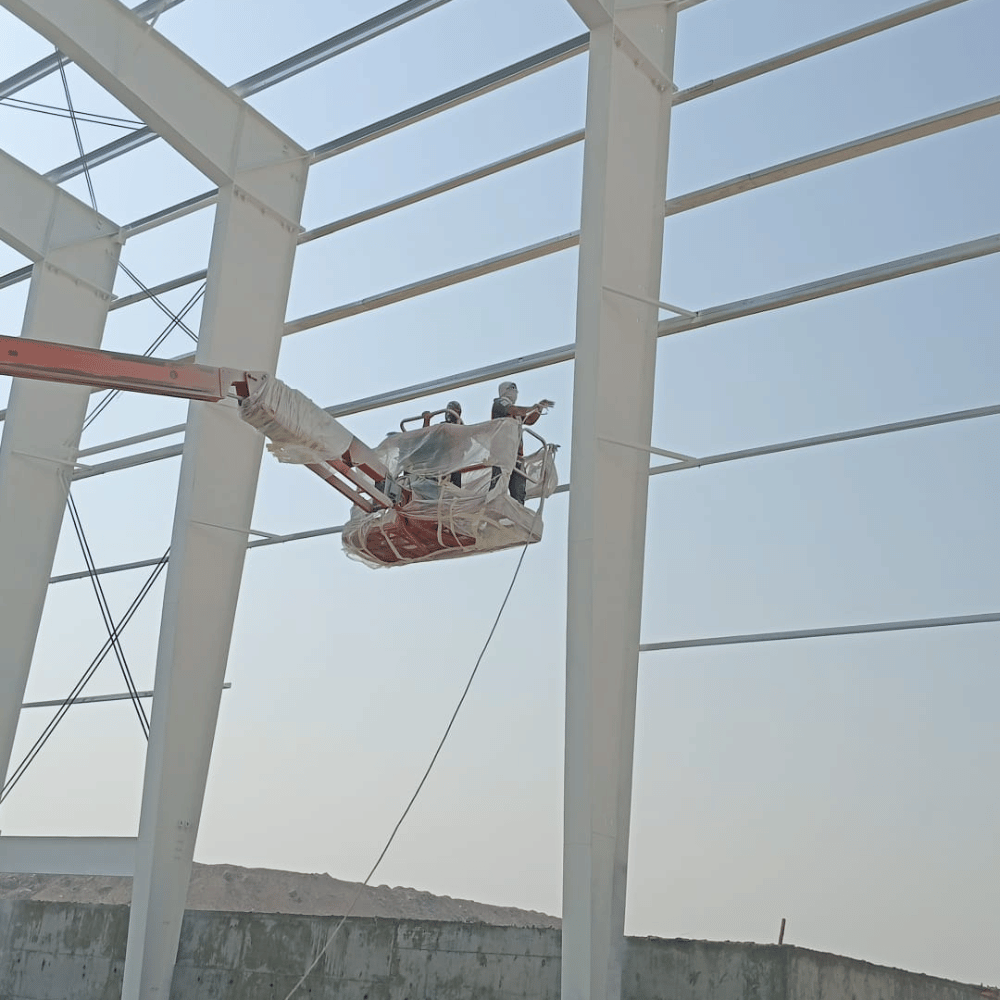

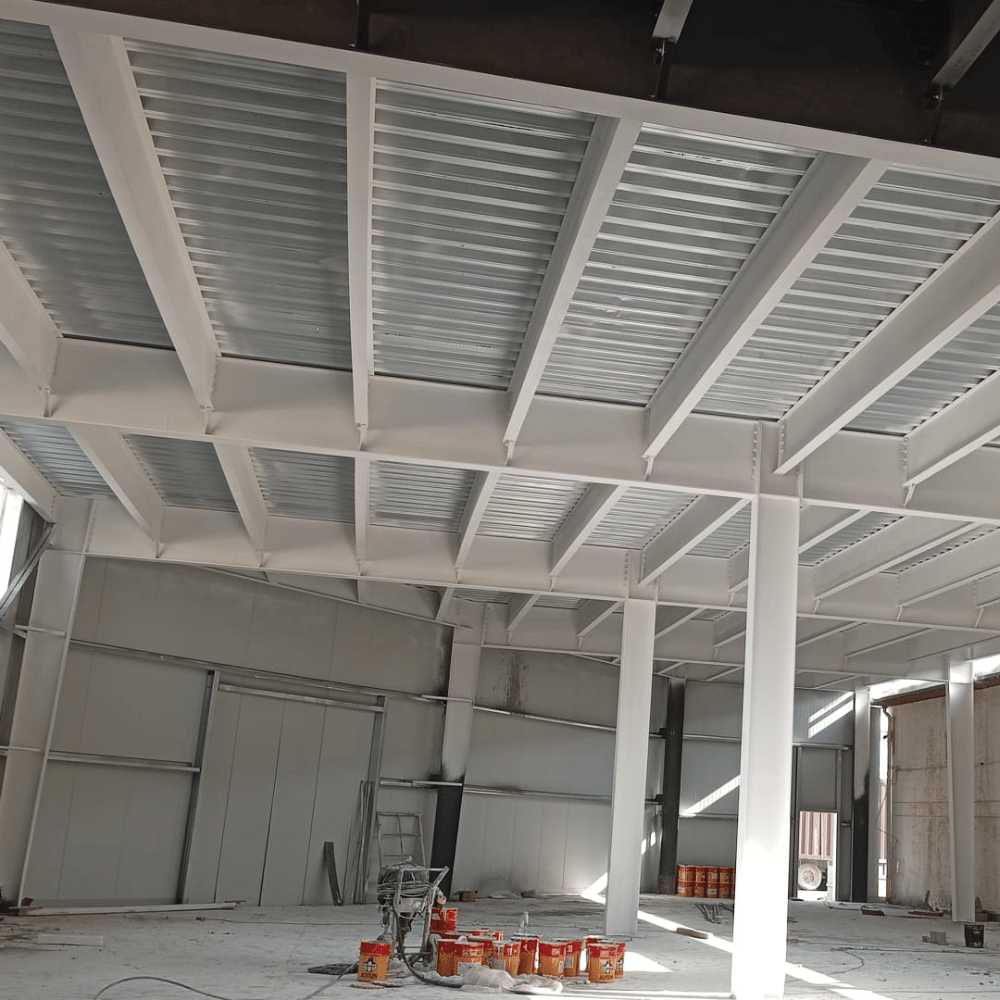

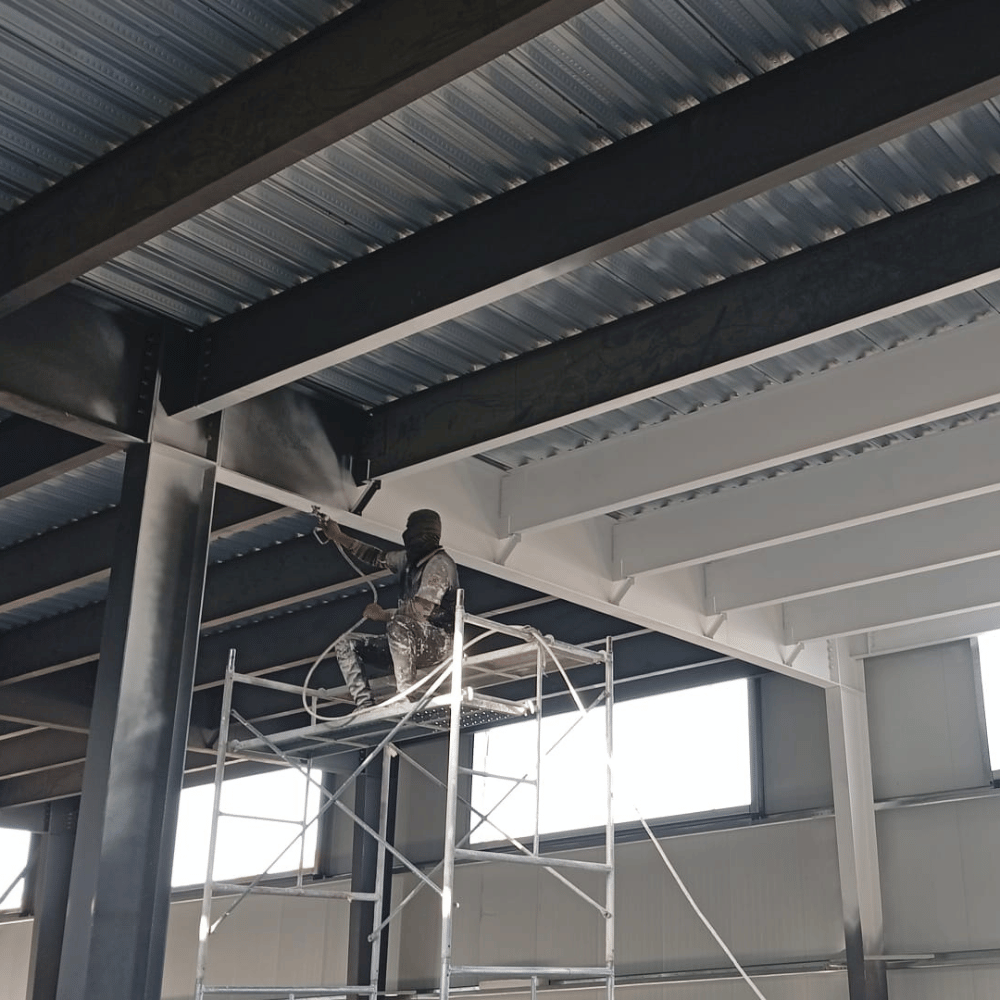

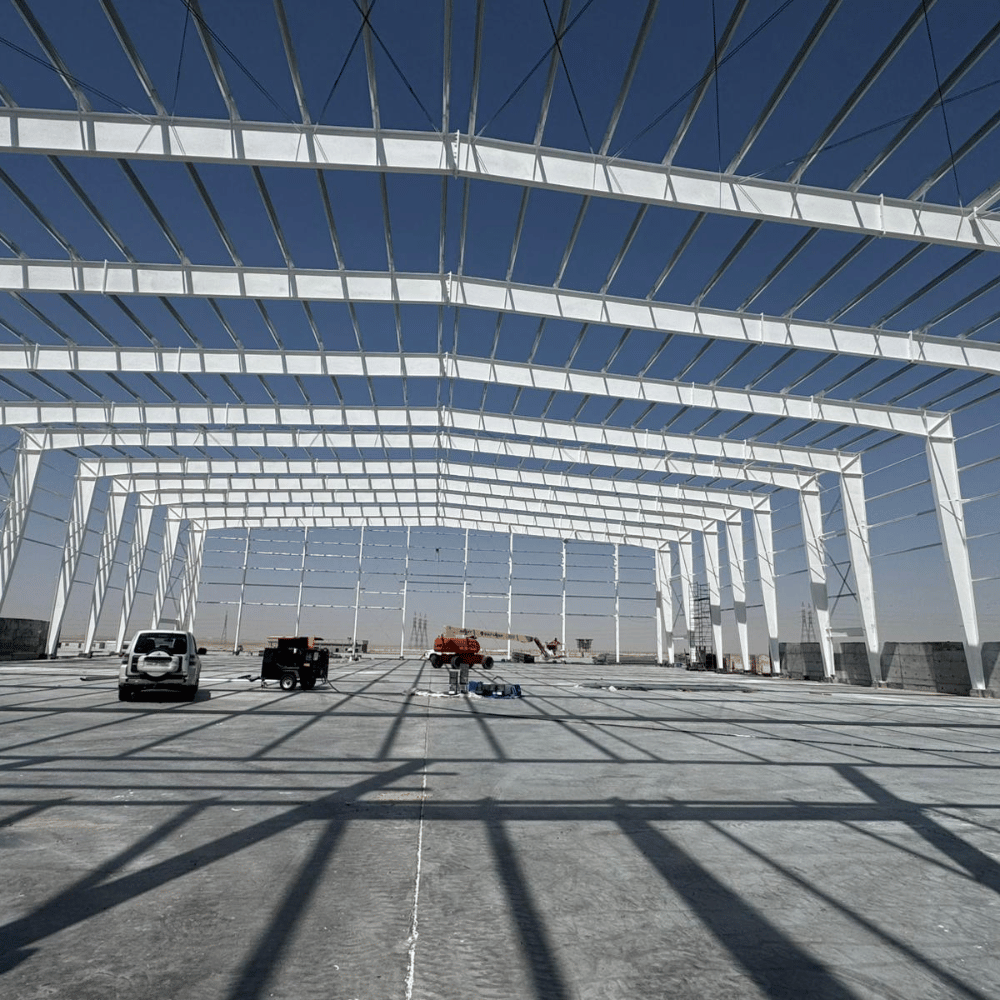

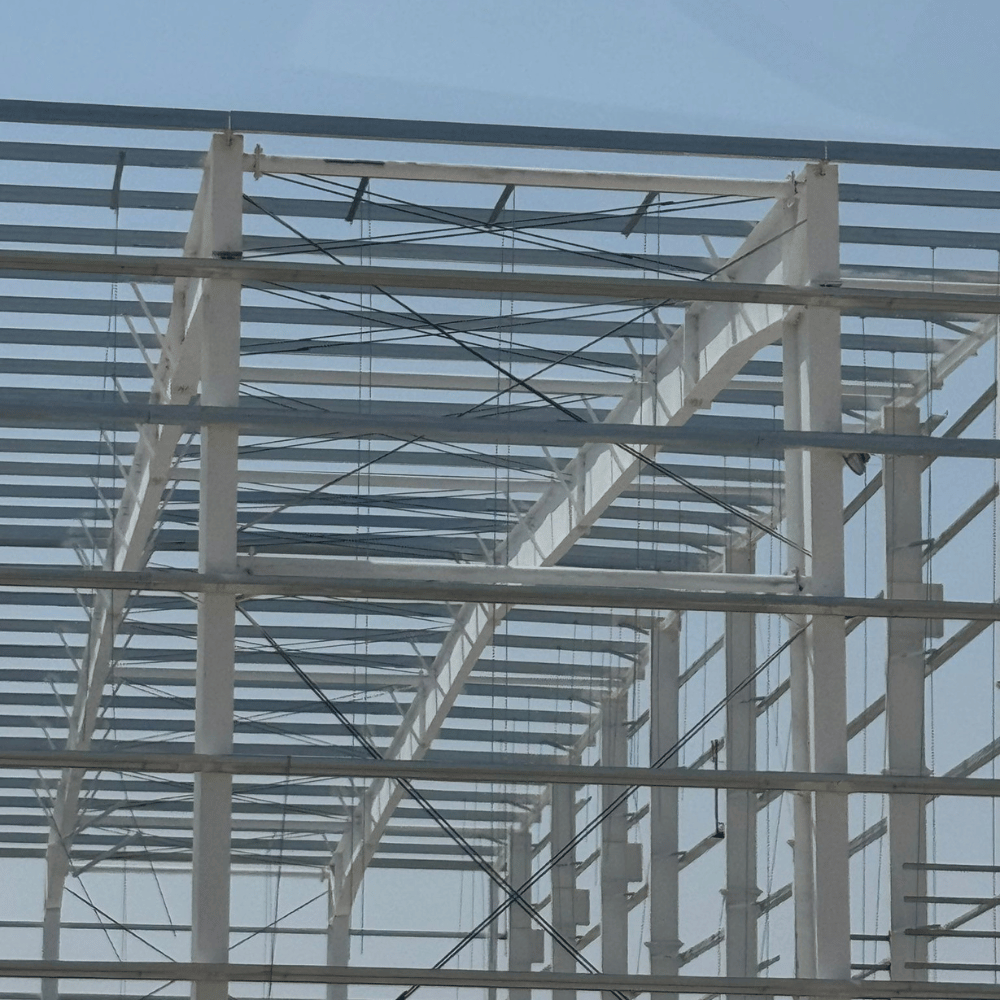

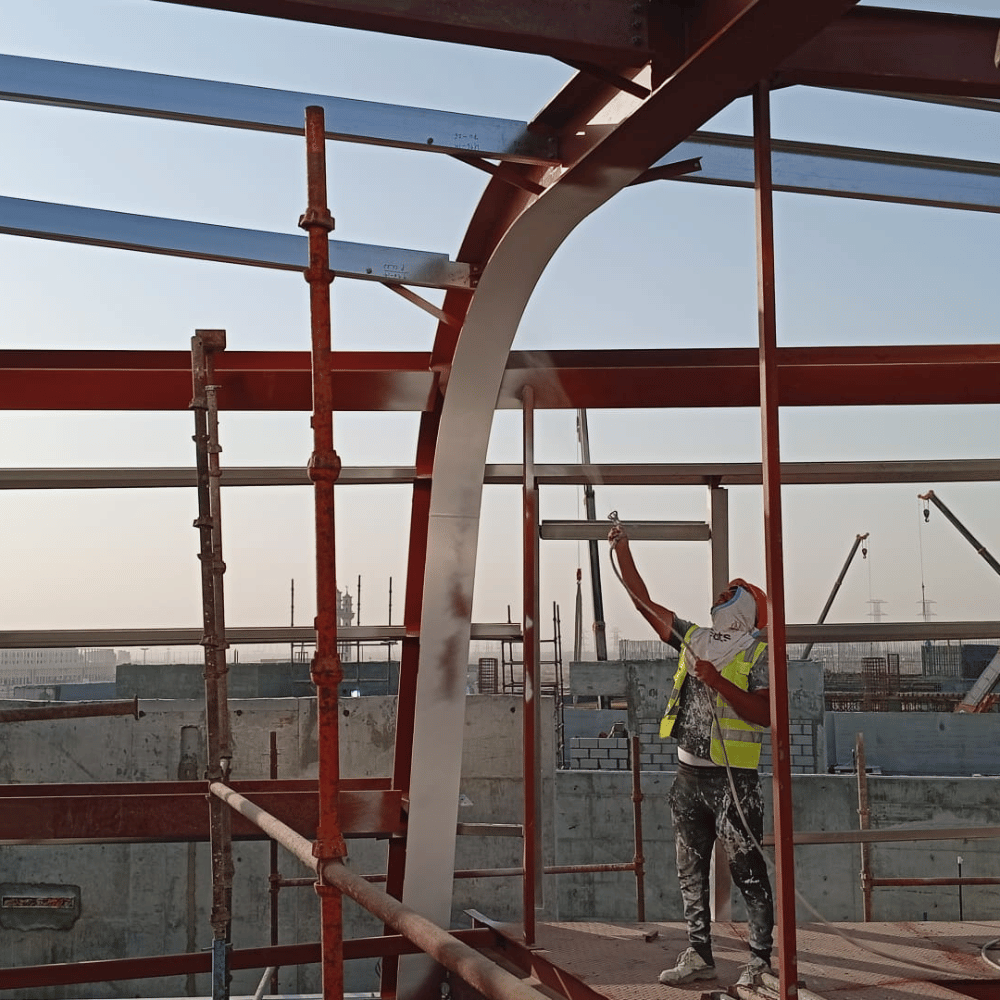

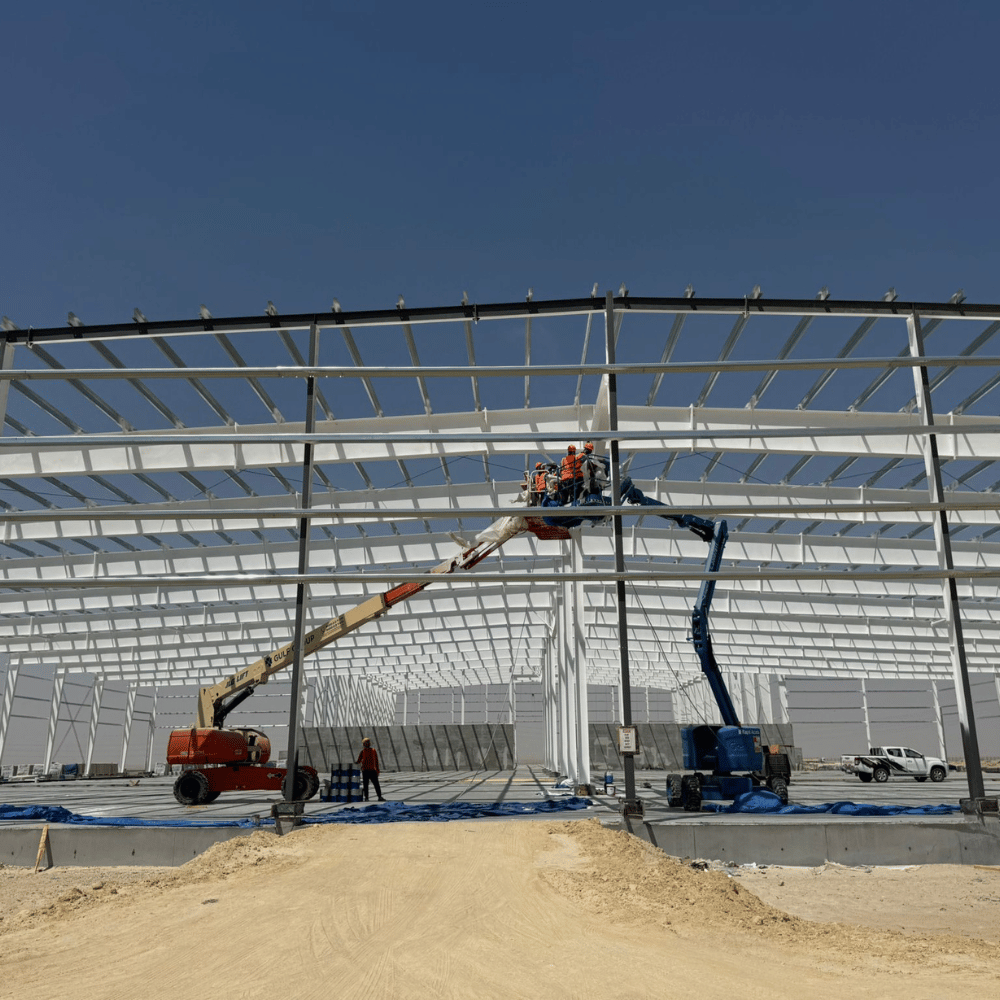

We deliver turnkey EPC services that protect, strengthen, and beautify your structures. From our Jeddah headquarters, our certified teams engineer, procure, and install four specialist solutions:

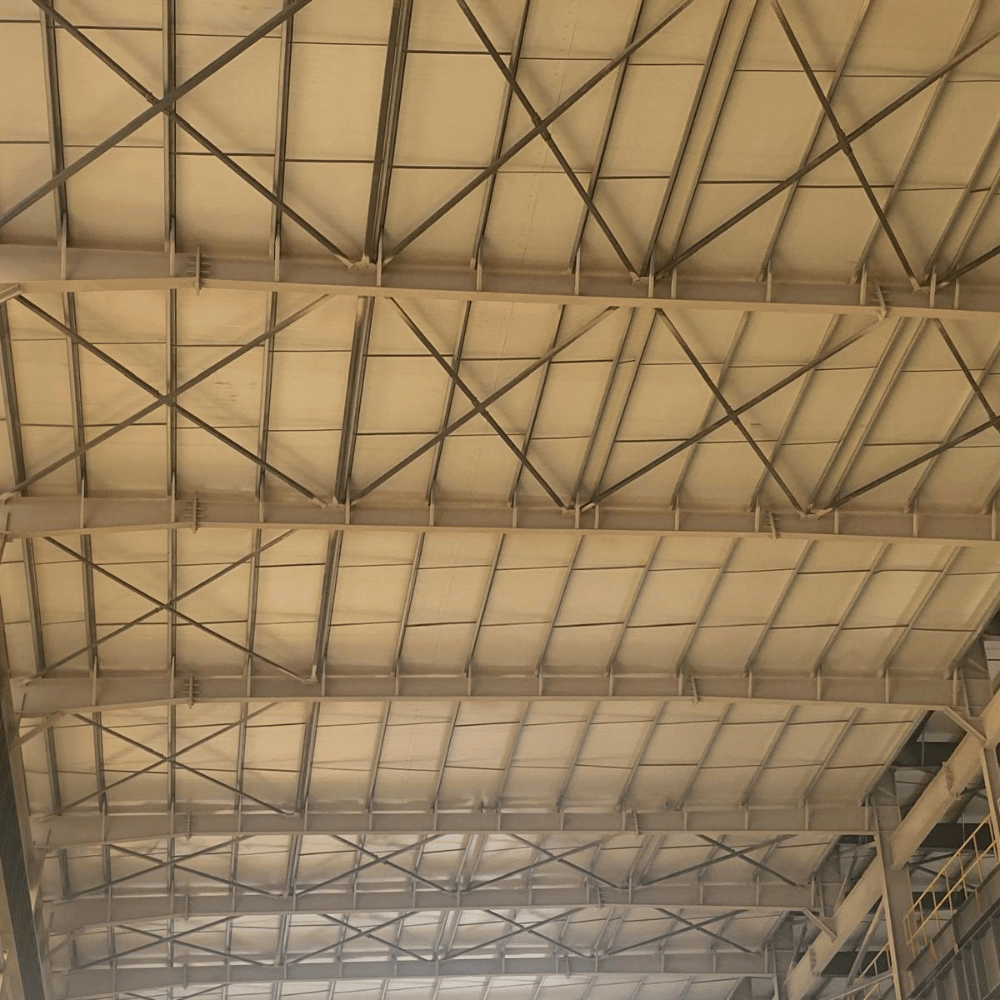

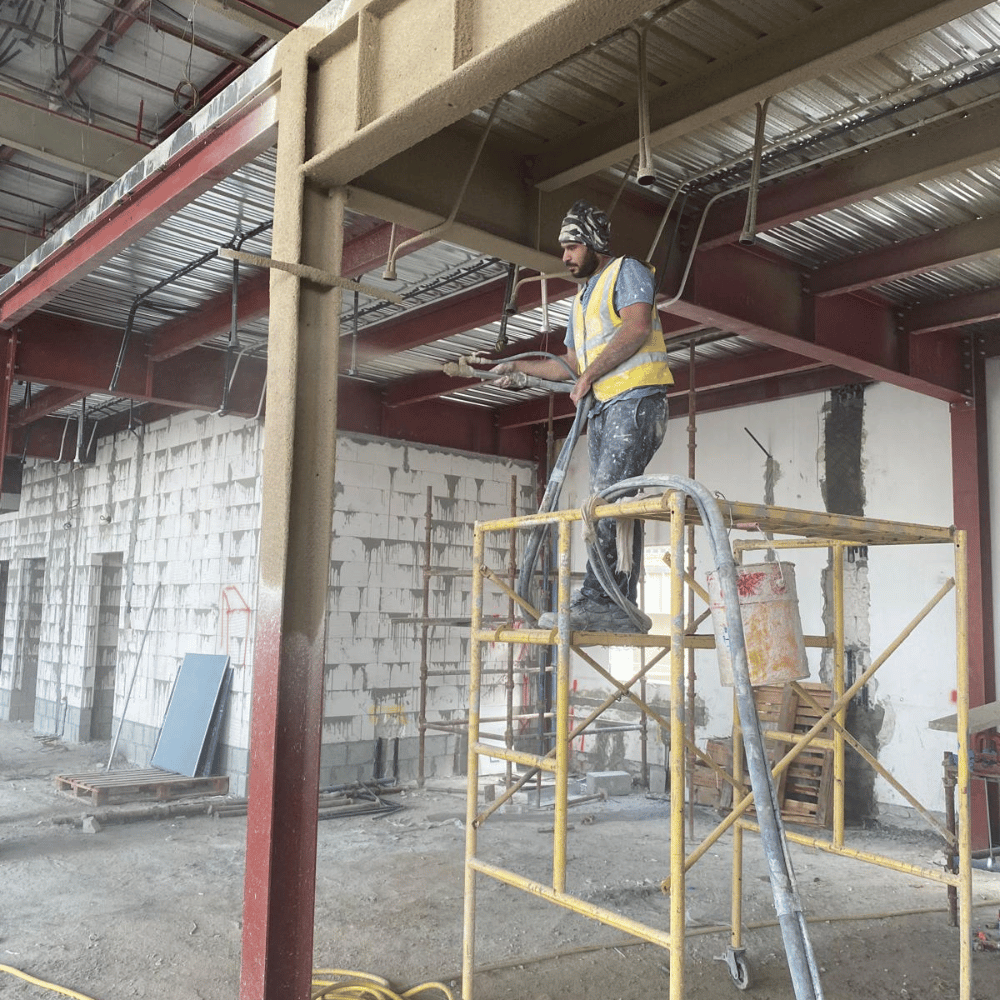

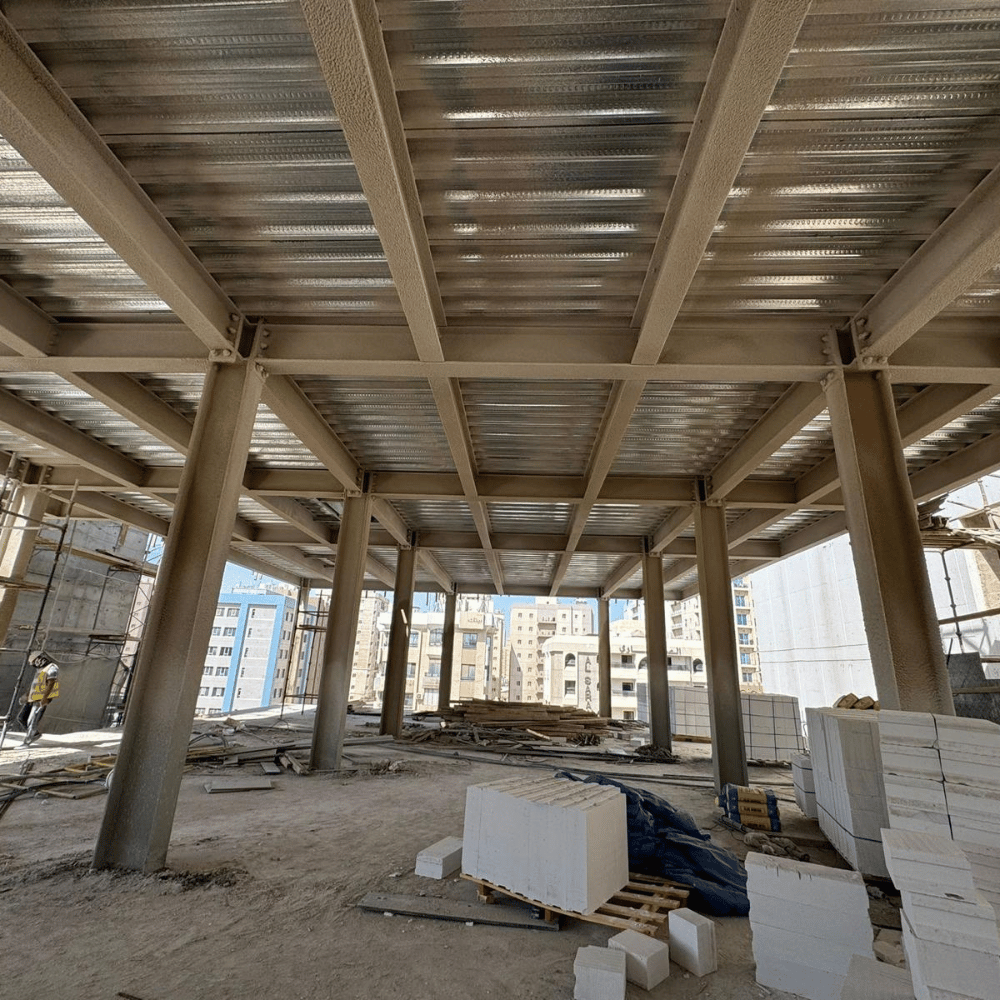

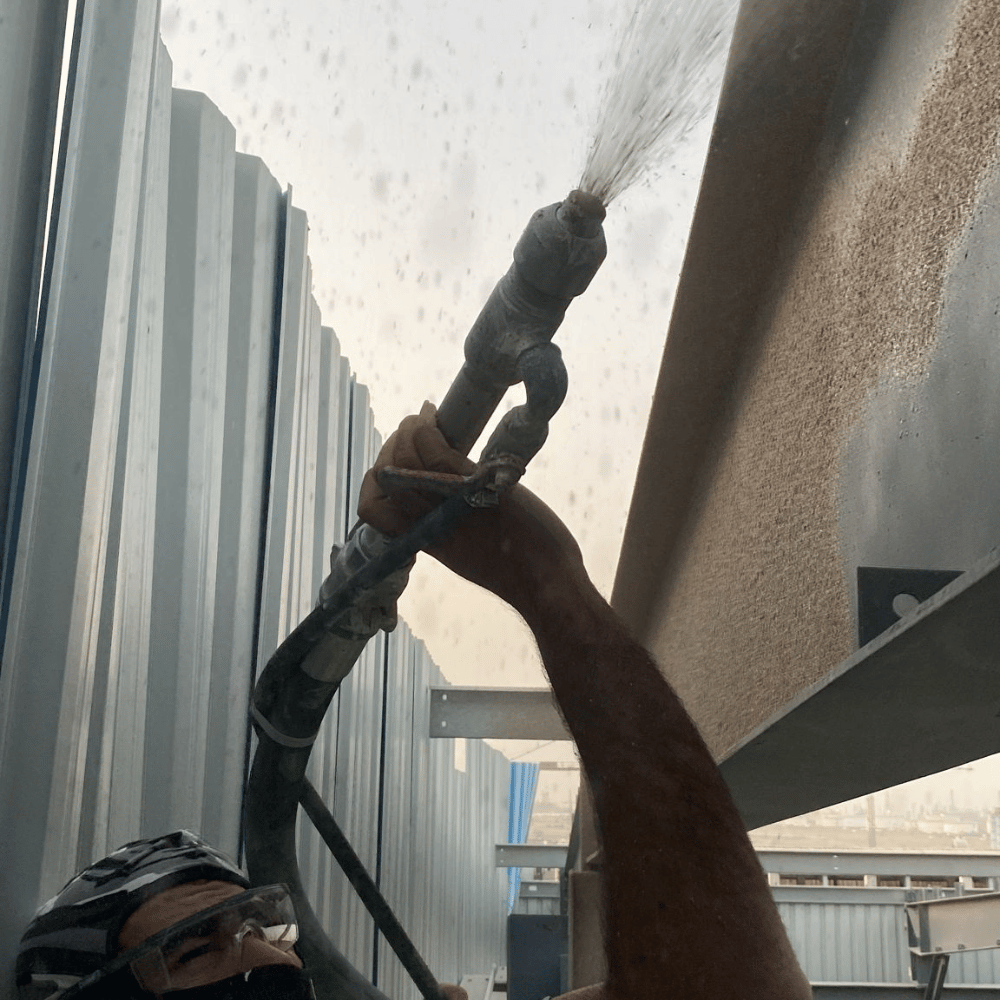

After our EPC services, we provide integrated solutions to protect and strengthen your metal structures while enhancing their appearance and fire resistance. From our headquarters in Jeddah, our certified teams handle all project stages: engineering, procurement, and installation, delivering specialized solutions in fit-out and fire-resistant metal coatings with the highest quality.

Whether your project is industrial, commercial, or civil, our integrated approach ensures consistency, accountability, and peak performance—every time.